A-Z Gids voor Flanel Fleece

WELKOM BIJ EDITEX Textiles

Sinds [1997] comfort creëren

Als een verticaal geïntegreerd fabrikant met 20+ jaar expertise, specialiseren we ons in premium polyester flanel fleece voor dekens en textiel.

Waarom kiest u ons?

Lage MOQ's – Schaalbaar voor starters & grosisten

Lage MOQ's – Schaalbaar voor starters & grosisten

Eco-gecertificeerd – OEKO-TEX® & GRS gecertificeerd materialen

Eco-gecertificeerd – OEKO-TEX® & GRS gecertificeerd materialen

Oplossingen van begin tot eind – Van stof tot afgeronde producten

Oplossingen van begin tot eind – Van stof tot afgeronde producten

Ontdek hoe onze duurzame textielen je lijn kunnen verheffen.

"Deze gids onderzoekt de unieke eigenschappen van natuurlijke flanelvloer, belangrijke onderscheiden ten opzichte van koralfleece en prestatievoordelen. We zullen het productieproces toelichten en veelgestelde vragen uit de industrie beantwoorden."

1. Wat is Flanelletje? Het ultieme comfortmateriaal

Flanel fleece is een delicate en zachte stof. Onze flanel bestaat uit polyestervezelmateriaal, en de oppervlakte wordt verwerkt met pluis, met kort en dicht pluis, wat een warme en comfortabele aanraking biedt. Flanel wordt breed gebruikt bij de productie van kleding, beddengoed en interieurdecoratie, dankzij zijn uitstekende isolatie-eigenschappen en comfortabele aanraking. De pluishaarverwerking kan de dikte en isolatie van de stof vergroten, terwijl er ook een zachte visuele textuur wordt toegevoegd, wat door consumenten zeer gewaardeerd wordt. Door zowel mode als functionaliteit in aanmerking te nemen, is flanel geworden tot een onmisbaar onderdeel van het dagelijks leven.

Gemaakt van hoogwaardige polyestervezels heeft onze flanelvloer een geborsteld oppervlak met een dichte, fluwelen structuur voor ongeëvenaarde zachtheid en warmte.

Waarom kiezen voor flanelvloer?

Het hele jaar door comfortabel – Lichtgewicht maar isolerend

Het hele jaar door comfortabel – Lichtgewicht maar isolerend

Veelzijdige toepassingen – Perfect voor loungewear, dekens en huisteksten

Veelzijdige toepassingen – Perfect voor loungewear, dekens en huisteksten

Premium Handfee l – Gepolijste finish verbetert zachtheid en houdbaarheid

Premium Handfee l – Gepolijste finish verbetert zachtheid en houdbaarheid

" Waar dagelijkse comfort samenkomt met uitzonderlijke kwaliteit – perfect voor coze momenten thuis. "

2. Wat zijn soorten van Flannel Fleece? Flannel Fleece Variëteiten & Aanpassingsmogelijkheden

(1). Verf

Op basis van de eisen van de klant, worden verschillende kleuren aan de flanel fleece toegevoegd.

(2). Print

Volgens de drukbehoeften van de klant, kiest men verschillende drukmethodes.

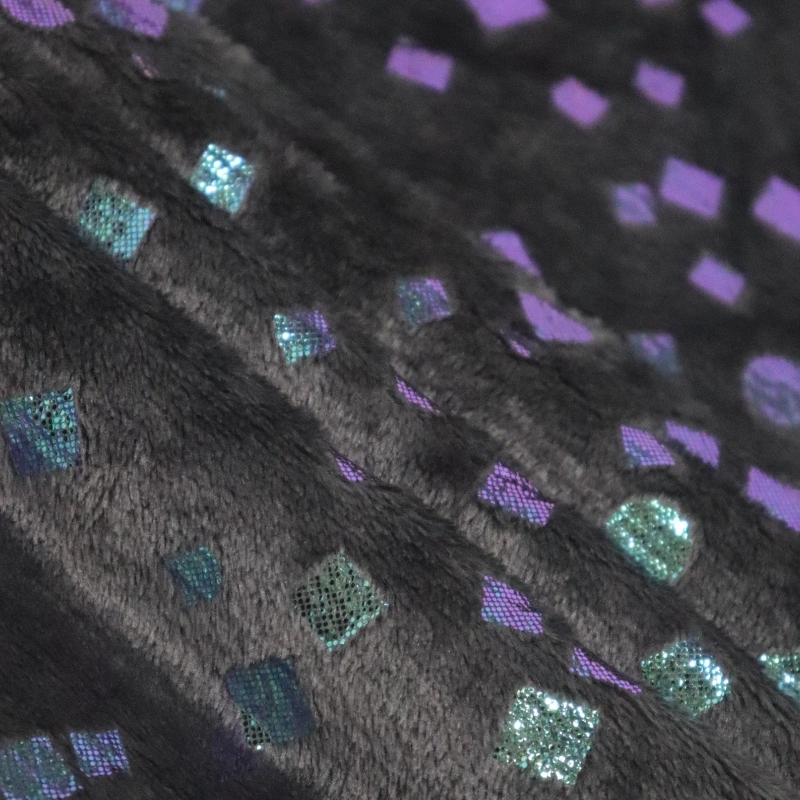

(3). Metaalfolie

Met behulp van hoge temperatuurwarmdruktechnologie wordt metaalfolie toegepast op flanel door warm stampen.

(4). Jacquard

Jacquard kunst niet alleen verhoogt de esthetische aantrekkelijkheid van stoffen, maar behoudt ook de zachtheid en comfort van flanel.

(5). Drukstempeling

Bij het drukken wordt het ontwerpplaatje op flanel gelegd en met een drukmachine in reliëf gedrukt op het oppervlak van de flanel.

(6). Knippen

Het knipproces van flanel houdt in dat er specifieke gereedschappen worden gebruikt om flanelstof in bepaalde patronen te knippen.

(7). Borstelen

Borstel de vloerbedekking volgens het ontwerp of patroon sjabloon in een richting om een driedimensionaal patroon of ontwerp te vormen.

(8). Nachtgloeiend / Luminair

Flanel lichtgevende stof is een deken gemaakt van een speciaal materiaal dat een lichtgevende functie heeft.

| Type | Beschrijving van het proces | Unieke Voordelen |

|---|---|---|

| Gekleurd Flannel | Aangepaste kleuropties om het merkidentity te behouden | Onbeperkte Pantone kleurmatch |

| Gedrukt | Digitale/drukpers afdrukken voor complexe ontwerpen | Hoog-oplosningspatronen tot 1200dpi |

| Metaaldrukfolie | Hittransfer folie stempelen | Creëert premium reflecterende oppervlakken |

| Schal | Ingeweven textuurpatronen | Patroonduurzaamheid zonder klossen |

| Met een breedte van niet meer dan 15 mm | 3D patroonpersing (0,5-3mm diepte) | Voegt een tactiele dimensie toe aan ontwerpen |

| Nauwkeurige Snede | Laser-geknipte stofvormen (±1mm nauwkeurigheid) | Perfect voor appliqué en patches |

| Geborsteld | Richtinggebonden vezelverheffing | Verbetert thermische isolatie met 30% |

| Glow-in-Dark | Behandeling met fosforpigment | 8+ uren lichtgevoeligheid na opladen |

Technische voordelen:

ECO PASSPORT gecertificeerde kleurstoffen

ECO PASSPORT gecertificeerde kleurstoffen

Wasvastheid: 50+ wasgangen

Wasvastheid: 50+ wasgangen

Pillenvorming weerstand: 4+ (ASTM D3512)

Pillenvorming weerstand: 4+ (ASTM D3512)

MOQ: 100 yard per ontwerp

MOQ: 100 yard per ontwerp

"Van concept tot afgeronde stof - we veranderen je visie in tastbare realiteit."

3. Verschillen tussen Flanel Fleece en Coral Fleece

(1). Verwerkingsmethode

Flanel heeft een extra stoomprocedure in het proces, maar coral velvet niet. Coral velvet wordt geweven met ronde gaten draad. Na afwerken en verven heeft de eindproduct van coral velvet een matte koraalachtige oppervlakte en een ruw gevoel. Op basis van het afwerk- en vervenproces van coral velvet wordt er een stoomproces toegevoegd voor flanel. Dus het eindresultaat van flanel toont een verticale vezelverdeling, een wolkig en glanzend materiaal, en een gladde en soepele aanraking.

(2). Gevoel bij aanraking

Bij aanraking voelt flanel comfortabeler aan door zijn fijnere textuur en zachte haptische eigenschappen. Coral voelt daarentegen warmer aan door zijn volumineuze pluizigheid en dikker textuur.

(3). Beschikbaarheid en Prijs

Ten eerste wordt flanel doorgaans oppervlakkig gevoerd om een kort en dicht pluizig laagje te vormen. Deze fluweelverwerking geeft flanel goede isolatie en een zachte aanraking, waardoor het geschikt is voor de productie van winterkleding, beddengoed en huisdecoraties. Zijn uiterlijk en tactiele ervaring zijn relatief zwaar, wat het geschikt maakt voor gebruik in koude weersomstandigheden.

In tegenstelling daarmee wordt koralfleece verwerkt met speciale plooien, wat resulteert in een oppervlakte die lijkt op koralen, met langere vezels en een lagere dichtheid. Koralfleece wordt vaak gebruikt in binnenkleding, babyproducten en beddengoed vanwege zijn zachte en comfortabele textuur, evenals goed vochtabsorptievermogen en adembaarheid. Zijn lichte verschijning is geschikt voor dragen in de lente- en herfstseizoenen of voor gebruik in gelimiteerde airco-omgevingen tijdens de zomermaanden.

(4). Certificering

We hebben een GRS-certificaat en hechten ook grote waarde aan het beschermen van het milieu bij de productie van onze producten. We hebben ook het OEKO-TEX-certificaat, dat de hele productieketen certificeert, en we hebben altijd gegeven om duurzame ontwikkeling in de textielindustrie.

Flanelletten vs. Coral Fleece: Belangrijkste verschillen

| Categorie | Van de soort gebruikt voor de vervaardiging van vellen | Koralenvlies |

|---|---|---|

| Productie |

- Extra strijkproces - Verticale draden verspreiding - Gepolijste oppervlakte |

- Gemaakt met rond gat gebreide wol - Geen strijkproces - Natuurlijke korstachtige textuur |

| Textuur |

- Kort, dicht geweven vilt (0,5-1,2mm) - Gladde, soepele gevoel - Lichte neerhang |

- Langere, losser pile (2-3mm) - Fluweelachtige, volumineuze handgevoel - Zwaarder gewicht |

| Prestatie |

- Betere isolatie (30% warmer) - Vocht afvoeren - Comfort het hele jaar door |

- Superieure adembaarheid - Sneller drogen - Ideaal voor lente/herfst |

| Toepassingen |

- Premium loungewear - Luxe beddengoed - Winteraccessoires |

- Babyproducten - Zomerdekens - AC-omgeving gedragen |

| CERTIFICERINGEN |

- GRS (Global Recycled Standard) - OEKO-TEX® Klasse I (Veilig voor baby's) |

- Dezelfde certificaten beschikbaar - Aangepaste opties mogelijk |

Duurzaamheidsvoordeel

Beide materialen komen samen:

OEKO-TEX® gecertificeerde productie

OEKO-TEX® gecertificeerde productie

GRS conformere recyclage materiaalopties

GRS conformere recyclage materiaalopties

Lage-impact waterbasis verven

Lage-impact waterbasis verven

"Kies flanel voor verfijnde oorlog mth, koraal voor ademende zachtheid - beide met milieuvriendelijke garantie. "

4. Hoe wordt Flannel Fleece gebruikt?

Flanellen stof en dekens worden breed uitgehouden voor hun comfort en praktischheid. Laten we hieronder gedetailleerd hun voordelen en toepassingen verkennen:

Voordelen van flanellen stof:

(1). Zacht en Comfortabel:

Flanellen stof met een zachte aanraking en een warm en comfortabel gevoel, geschikt voor de winter en huishoudelijke artikelen.

(2). Isolatieprestaties:

Vanwege zijn hoge vlokdichtheid heeft flanellen stof goede thermische isolatieprestaties, wat effectief koude lucht van buiten blokkeert en het lichaam warm houdt.

(3). Vochtigheidsopname en adembaarheid:

Flanellen stof heeft goede vochtabsorptie en adembaarheid, waardoor het snel zweet van de huidoppervlakte kan opnemen en weer vrijgeven, waardoor de huid droog en comfortabel blijft.

(4). Slijtstroom bestandheid:

Vanwege zijn dichte structuur hebben flanellenstoffen meestal goede slijtagebestendigheid, duurzaamheid en raken ze niet snel versleten.

De toepassing van flanel:

(1). Inrichting voor thuisgebruik:

De zachte en comfortabele eigenschappen van flanel maken het een ideale keuze voor het vervaardigen van huishoudelijke artikelen zoals dekens, kussens, bankoverdekken, etc., wat warmte toevoegt aan de thuisomgeving.

(2). Babyproducten:

Voor baby's is de zachtheid en warmte van flanel zeer geschikt om babybedding en dekens te maken die hun gevoelige huid beschermen.

(3). Versieringen:

Flanel heeft rijke kleuren en kan worden gebruikt om vakantieversieringen of thuisdecoraties te maken, wat feestelijke sfeer toevoegt of de decoratieffecten van de woning verbetert.

Flanellet: Het Ultieme Comfortmateriaal

Beroemd om zijn uitzonderlijke zachtheid en veerkracht, is flanellet een premium keuze voor zowel huishoudelijke als levensstijlproducten.

Belangrijkste voordelen

| Kenmerk | Voordelen | Ideaal is voor |

|---|---|---|

| Uitgebreide Zachtheid | Geborsteld oppervlak creëert een fluwelen, huidvriendelijke textuur | Gevoelige huid- en babyproducten |

| Thermische regulering | Hoge vilt dichtheid vangt warmte op (30% betere warmte-isolatie dan katoen) | Winterkleding en kouweerklimaat beddengoed |

| Vocht wegnemen | Neemt snel vocht op en laat dit verdampen (droogt 2x sneller dan wol) | Actieve loungewear en nachtkleding |

| Duurzaamheid | Strakke weefsel weerstaat kloppen (50+ wasbeurten) | Veelgebruikte huishoudartikelen |

Premiumpressingen

Thuisbasisbehoeften

Thuisbasisbehoeften

Dekens: Jaaromspannend comfort met ademende warmte

Versierende dekens: 200+ kleur/patroonopties

Kussenhoezen: Zacht, maar gestructureerd voor dagelijks gebruik

Baby veilig

Baby veilig

OEKO-TEX® gecertificeerde babybedding

Hypoallergene wiegdekens

Beschermende kinderwagenoverkleden

Levensstijl

Levensstijl

Hotelkwaliteit badjassen

Hotelkwaliteit badjassen

Omkeerbare picknickblanken

Omkeerbare picknickblanken

Seizoensgebonden huishoudelijke versieringen (vakantie tafelrunner etc.)

Seizoensgebonden huishoudelijke versieringen (vakantie tafelrunner etc.)

Voordelen van dekens:

(1). Warmte:

Een deken is een algemene vorm van flanelstof die extra warmte biedt en geschikt is voor gebruik in bedden, banken of buiten.

(2). Multifunctioneel:

Naast het gebruik voor warmte kunnen dekens ook worden gebruikt als decoratieve items of zitkussens om de behoeften van verschillende situaties te dekken.

(3). Makkelijk te reinigen:

De meeste flaneldakens zijn gemakkelijk te reinigen en onderhouden, en kunnen in de wasmachine of handmatig worden gewassen om schoonheid en hygiëne te handhaven.

Het doel van de deken:

(1).Slapen producten:

Dakens zijn uitstekende slaapgezellen, ze bieden comfortabele warmte en helpen mensen hoge kwaliteit slaap te krijgen.

(2). Interieurdecoratie:

Dekens zijn niet alleen praktisch, maar kunnen ook worden gebruikt om binnenruimtes te versieren, bij het interieur te passen en een thuisatmosfeer toe te voegen.

(3). Buitenactiviteiten:

Dekens zijn ook zeer praktisch bij buitenactiviteiten, zoals picknicks, kamperen of bij het kijken naar openluchtactiviteiten, waarbij extra warmte kan worden geboden.

Flanellen dekens: Warmte ontmoet veerkracht

Belangrijkste voordelen

| Kenmerk | Voordelen | Beste gebruiksgevallen |

|---|---|---|

| Warmte voor alle seizoenen | Hoge dichtheid vangt warmte effectief op (+5°C vergeleken met katoen) | Beddengoed voor koude weersomstandigheden & buitengebruik |

| 3-in-1 Functionaliteit | Kan omgezet worden tussen: 1) Dekensprei 2) Versieringsaccent 3) Zitkussen | Woonkamers, studentenkamers, Airbnb-ruimtes |

| Minimale onderhoudsbehoefte | Machinespoorbaar (40°C) met anti-pilling behandeling | Geschikt voor drukke huishoudens en hospitality-gebruik |

Premiumpressingen

Slaapverbetering

Slaapverbetering

Bed Toppers: Voegt 30% warmte toe zonder gewicht

Gewichtsdekens: Ideale zachte basislaag

Nursery Essentials: OEKO-TEX® gecertificeerd voor baby's

Woningstijl

Woningstijl

Accent dekens: 50+ ontwerpcolorways

Modulair decor: Omkeerbaar voor seizoensgebonden thema's

-

Vriendelijk voor huisdieren: Krasschade-bestendige texturen

Avontuur klaar

Avontuur klaar

Compacte reisdekens (vouwt tot 25x25 cm)

Compacte reisdekens (vouwt tot 25x25 cm)

Waterafstotende achterzijde-opties

Waterafstotende achterzijde-opties

Stadionstoelen met draagriemen

Stadionstoelen met draagriemen

Samenvattend spelen flanelstoffen en dekens een belangrijke rol in het gezinsleven vanwege hun zachtheid, comfort, isolatieprestaties en diversiteit aan toepassingen. Of het nu gaat om het warm blijven in de koude winter of als comfortabele decoraties in de warme zomer, ze bieden mensen praktische en aangename ervaringen.

Flanel Essentials: Comfort voor elk seizoen

Flanellen stoffen en dekens zijn onmisbaar geworden in moderne huizen, ze bieden:

Jaaromtrekwaarde

Winter: Uitstekende isolatie houdt lichaamswarmte 30% effectiever vast dan katoen

Zomer: Ademende varianten (170-350GSM) behouden comfort in AC-omgevingen

Alle seizoenen: Eigenschappen voor vochtverwijdering reguleren temperatuur

Waarom Huizen Flanel Liefhebben

Multifunktioneel ontwerp: Verandert in seconden van beddengoed tot versierende deken

Multifunktioneel ontwerp: Verandert in seconden van beddengoed tot versierende deken

Premie Kumfort: OEKO-TEX® gecertificeerde zachtheid, veilig voor alle leeftijden

Premie Kumfort: OEKO-TEX® gecertificeerde zachtheid, veilig voor alle leeftijden

Duurzame prestaties: Houdt 50+ industriële wasbeurten vol zonder te pillen

Duurzame prestaties: Houdt 50+ industriële wasbeurten vol zonder te pillen

"Meer dan stof - het is de kunst van dagelijkse comfort volmaakt gemaakt door vakmanschap."

5.Waar wordt polyesterspoel geproduceerd?

Polyestervezel kan wereldwijd worden geproduceerd. Bijvoorbeeld, China is een van de belangrijke landen. Polyestervezel wordt gevormd door te spinnen, waarna de polyestervezel wordt verwerkt tot onbewerkt textiel. Wij zijn toegewijd aan de duurzame ontwikkeling van polyesterstoffen, EDITEX kan de bescherming van het milieu tijdens het productieproces garanderen om duurzame praktijken te realiseren.

We hebben certificaten om ons te bevestigen:

-GRS

-OEKO-TEX

Wereldwijde productie van polyesters vezel r

Polyestervezel wordt wereldwijd geproduceerd, met China als een vooraanstaande producent. Het productieproces omvat:

Spinnen: Rauw polyester wordt gedraaid tot fijne vezels

Weven/Breien: Vezels worden verwerkt tot grijze stof

Afwerking: Stof ondergaat verven, printen en behandeling

EDITEX' Duurzaamheidsbelofte

GRS Gecertificeerd: Garandeert gerecycled inhoud in onze polyester

GRS Gecertificeerd: Garandeert gerecycled inhoud in onze polyester

OEKO-TEX Gecertificeerd: Garandeert veilige, niet-toxische materialen

OEKO-TEX Gecertificeerd: Garandeert veilige, niet-toxische materialen

Milieu-vriendelijke productie: Implementeert energie-efficiënte en weinig afval producerende processen

Milieu-vriendelijke productie: Implementeert energie-efficiënte en weinig afval producerende processen

" Verantwoordelijk innoveren in textielen - voor kwaliteit waar je op kunt vertrouwen en een planeet die we beschermen. "

6. Zijn flanel en fleece hetzelfde?

Nee, ze zijn niet hetzelfde.

Flanel is een van de fleece soorten, wat betekent dat flanel onder fleece valt. Flanel is een zachte, suèdeachtige stof. Deze werd in de 18e eeuw in Wales, Engeland, ontwikkeld. Flanel heeft veel fijne en goed gevoelende vacht bedekt. En het heeft geen zichtbare weefselstructuur. Het voelt zacht en glad. Flanel heeft eenvoudige, frisse en generieuze kleuren, een hoge gewichtsgraad, meer fijne en dichte pluis, een dikke stof, hoge kosten, en goede warmte-isolatie.

Hoewel, fleece heeft veel verschillende soorten. Bijvoorbeeld, niet alleen flanel, maar ook sherpa, polaire wol en valse bont horen allemaal bij fleece. "FLEECE" is gewoon een verzamelnaam.

Als je meer over hen wilt weten, ga www.editextile.com voor meer informatie.

Flanel versus Fleece: Het verschil begrijpen

Nee, flanel en fleece zijn niet hetzelfde - flanel is een type soort van fleece met unieke kenmerken.

Sleutelvergelijking

| Kenmerk | Flanel | Vlies (Algemeen) |

|---|---|---|

| Herkomst | Ontwikkeld in Wales in de 18e eeuw | Breed categorie van stoffen |

| Textuur | Uiterst zacht, geborsteld oppervlak (geen zichtbare weefselstructuur) | Varieert (Sherpa, polar, valse bont, etc.) |

| Gewicht & Warmte | Hoog GSM, dichte plush, uitstekende isolatie | Varieert van lichtgewicht tot zwaar |

| Uiterlijk | Schoon, eenvormige kleuren; premium afwerking | Verschillende texturen (pluizig, geribd, etc.) |

| Kosten | Hoger door geavanceerde vakmanschap | Breed prijsbereik op basis van type |

Waarom Flanel Kiezen?

Uitgebreide Zachtheid – Delicaat, suède-achtig handgevoel

Uitgebreide Zachtheid – Delicaat, suède-achtig handgevoel

Uitzonderlijke warmte – Ideaal voor koude klimaten

Uitzonderlijke warmte – Ideaal voor koude klimaten

Elegante Eenvoud – Tijdloze, veelzijdige stijl

Elegante Eenvoud – Tijdloze, veelzijdige stijl

"Flanel is de top van vlees—waar premium comfort samenkomt met duurzame kwaliteit."

ONTDEK MEER

Voor gedetailleerde stofgidsen, bezoek: www.editextile.com

7. Wat zijn de soorten van Flanel Fleece?

(1). Printen

①. Plat schermprinten:

Hoewel de productie van plat gescreend flanel laag is, is het gemakkelijk om te platen en heeft het een grote herhaling van het scherm. Tegelijkertijd biedt het veel keuzes voor chromatografie en kan een geavanceerd patroon individueel worden gedrukt. De hoeveelheid drukinkje is groter met zijn driedimensionale patroon. Het is geschikt voor polyester gebreide patronen. En beter aangepast aan hoogwaardige gebreide drukken.

②. Rotatieschermprinten:

Deze techniek wordt meestal gebruikt voor cyclische patronen. Het gebruikt een rabbler om de basis in het rotatiescherm te drukken op de gebreide stof. Rotatieschermprint heeft een hoge snelheid, lage onderhoudskosten en is eenvoudig te bedienen. Het patroon is echter ruwer dan bij plat schermprinten.

③. Digitale printen:

Op basis van de computer techniek, wanneer de computertechnologie sneller groeit, zijn de machine en de computertechnologie samengevoegd. Digitale printing bestaat eruit om het patroon RIP naar de digitale printmachine te importeren en direct op de stof te printen met een inkjet. Omdat het inkjetten op vraag gebeurt, zullen chemicaliën en afvalwater verminderd worden. Deze printmethode heeft een beschermend effect op het milieu. Maar op deze manier kunnen bij sommige subtielere kleuren in het eindproduct kleurafwijkingen optreden.

Vergelijking van drukmethoden voor flanel en fleece

| Druktype | Beschrijving van het proces | Voordelen | Beperkingen | Bestemd Voor |

|---|---|---|---|---|

| Vlak scherm | Handmatige schermprint met platen |

- Hoge precisie voor details - Grote kleurenreeks - Uitmuntend voor complexe ontwerpen |

Trage productiesnelheid Hoger Kosten |

Luxe/hoogwaardige flanelproducten |

| Rotatiescherm | Geadverteerd cilinderschermprinten |

- Snel productieproces - Lage exploitatiekosten - Consistente herhalingen |

Beperkte ontwerppachtigheid Grovere details |

Massaproductie van cyclische patronen |

| Digitaal | Computergecontroleerd inkjetdrukken |

- Milieuvriendelijk (minder afval) - Onbeperkte ontwerpmogelijkheden - Snel monsteromzettingsproces |

- Kleurwinstuitdagingen - Hogere inktkosten |

Aangepaste ontwerpen/Kleine series |

Belangrijkste technische opmerkingen:

Kleur nauwkeurigheid: Vlak scherm > Digitaal > Rotary

Productiesnelheid: Rotary > Digitaal > Vlak

Opstelkosten: Vlat > Draaiend > Digitaal

Milieubelasting: Digitaal gebruikt 60% minder water dan traditionele methoden

Focus op duurzaamheid:

Alle onze drukmethodes voldoen aan:

OEKO-TEX® Standard 100

GRS (Global Recycled Standard)

BlueSign® gecertificeerde inkt

"Van boutiquestoontwerpen tot massa-productie - wij bieden de perfecte drukoplossing voor elke flaneltoepassing. "

7.1 Het verschil tussen vlakbedruk, cilinderbedruk en digitale bedruk

Voor de bedrukking van vlaaiende dekens, verschillende bedrukkingsmethodes kiezen (vlakbedruk, cilinderbedruk, digitale bedruk) zal verschillende effecten en toepasbaarheid hebben. De belangrijkste verschillen tussen hen in de vlaaiende dekenbedruk zijn als volgt:

— Vlakbedruk —

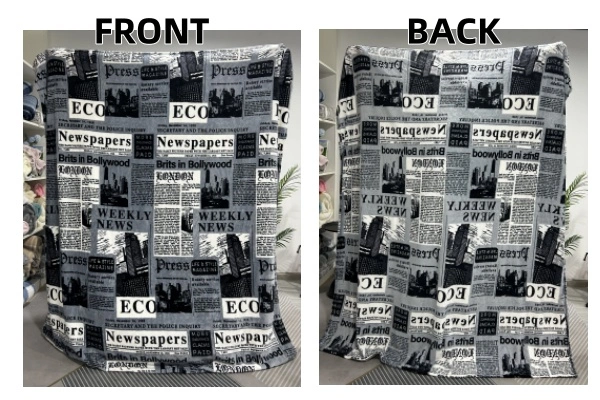

Principe : Plat drukken gebruikt een plat scherm om inkt door de meshgaten van het scherm op een velpen deken te drukken. Het scherm ligt meestal plat. (Dubbele kanten hebben patroonontwerpen)

Voordelen :

Brede toepasbaarheid : Het kan gedrukt worden op verschillende materialen, waaronder velpen dekens.

Levendige kleuren : In staat om rijke kleuren te bieden en heldere drukresultaten te bereiken.

Matige kosten : Geschikt voor kleine en middelgrote productie, met relatief lage beginvoorbereidingskosten.

Nadelen :

Relatief trage productiesnelheid : Lage productie-efficiëntie, niet geschikt voor zeer grote schaalproductie.

Beperkte beeldprecisie : Geschikt voor grote vlakken en eenvoudige patronen, met minder aandacht voor details dan digitale druk.

Toepassing : Geschikt voor kleine en middelgrote productie van velpen dekens, vooral voor het ontwerp van grote vlakken of eenvoudige patronen.

— Rotogravure-drukken —

Principe : Rotogravure-drukken gebruikt een cilindrische scherm om inkt op een vlaaiende deken aan te brengen door de gaten op het scherm. (Dubbele kanten hebben patroonontwerpen)

Voordelen :

Hoge drukkwaliteit : In staat om uniforme dekking van hoge-kwaliteit afbeeldingen en kleuren te bereiken, vooral geschikt voor grote oppervlakken van kleurvlakken en patronen.

Sterke duurzaamheid : De drukresultaten zijn langdurig en slijtstofbestendig.

Geschikt voor massa-productie : Hoge productie-efficiëntie, geschikt voor massa-productie, lage eenheidskosten.

Nadelen :

Hoge beginkosten : Vereist de productie van circulaire schermdrukken en apparatuur, met een aanzienlijke initiële investering.

Moeilijkheid bij ontwerpmodificatie : Nadat het ontwerp is vastgesteld, is het moeilijk aan te passen en niet geschikt voor vaak veranderende ontwerpeisen.

Toepassing : Geschikt voor grote schaal productie van flanel dekens, vooral voor ontwerpen met eenvoudige patronen of grote kleurvlakken.

— Digitale Druk —

Principe : Digitale druk betekent het direct overbrengen van digitale afbeeldingen op stof en het gebruik van digitale printers voor het afdrukken. (De voorkant heeft een gepatrouilleerd ontwerp, terwijl de achterkant wit is)

Voordelen :

Hoge precisie en detail : In staat om hoge resolutie afbeeldingen en complexe details te bereiken, geschikt voor het ontwerpen van complexe patronen.

Sterke flexibiliteit : Geschikt voor kleine serieproductie en personalisatie, met eenvoudige en gemakkelijke ontwerpwijzigingen.

Rijke kleuren : Het kan nauwkeurige weergave van gradientenkleuren en veelkleurigheid bereiken, en het beeldresultaat is fijngevoelig.

Nadelen :

Relatief hoge kosten : Bij massaproductie is de eenheidskost relatief hoog.

Materiaalverwerking : De toepasbaarheid op bepaalde speciale materialen is slecht, maar moderne technologie heeft dit verbeterd.

Toepassing : Geschikt voor kleine series of gepersonaliseerde flanel dekens die hoge precisie en diverse patronen vereisen.

- samenvatting -

Vlakbedrukken: Geschikt voor kleine en middelgrote producties van flanel dekens, geschikt voor grote kleurvlakken en simpele ontwerpen, met relatief matige kosten.

Cirkeldruk: Geschikt voor grote schaalproductie van flanel dekens, vooral voor uitgebreide patronen en kleurvlakken, met hoge productie-efficiëntie maar hoge initiële kosten.

Digitale druk: Geschikt voor gepersonaliseerde, kleine serie, hoge precisie flanel dekens, in staat om complexe patronen en details te realiseren.

Vergelijking van Flaneldekens Drukmethoden

| Methode | Bestemd Voor | Voordelen | Beperkingen | Kosten-efficiëntie |

|---|---|---|---|---|

| Vlak scherm |

Kleine/middelgrote series Eenvoudige ontwerpen |

- Kleurrijke kleuren - Lage opstelkosten - Dubbelzijdige afdruk |

Langzame Snelheid Beperkt detail |

Medium (kleine series) |

| Rotatiescherm |

Massa Productie Vaste kleurblokken |

- Snel productieproces - Duurzame prints - Dubbelzijdige afdruk |

## Hoge initiële kosten Onbuigzame ontwerpen |

Hoog (grote hoeveelheden) |

| Digitaal |

Aangepast/hoog-detaillering ontwerpen Kleine series |

- Fotografische details - Gemakkelijke ontwerpwijzigingen - Milieuvriendelijk |

Hoger eenheidskostprijs Enkelzijdig alleen |

Laag (onder 500 eenheden) |

(2). Kleuren

Verf en noodzakelijke additieven voorbereiden volgens de vereiste kleurformule. Bij het kiezen van verfstoffen moet rekening worden gehouden met de eigenschappen van fluweel om te zorgen dat de kleur na het verven gelijkmatig en vast blijft. Voorbehandeling van fluwelen stof, inclusief weken en spoelen, om oppervlakte-resten te verwijderen en de verfopname te verbeteren. Gebruik wekmachines of vervenmachines voor het verven om te zorgen dat de verf volledig in de stof doordringt. Temperatuur en tijd nauwkeurig controleren tijdens het verven om gelijkmatige en consistente vervenresultaten te behalen. Na het verven de fluwelen stof spoelen met schoon water om overtollige verf en stoffen te verwijderen. Kwaliteitscontrole uitvoeren op de gekleurde stof om gelijkmatige kleur en standaard kleurvastheid te garanderen en controleer op schade of inkrimping.

Overzicht van het Vervenproces van Fluweel

1. Verfvorbereiding

- Selecteer verfstoffen & additieven op basis van de kleurformule

- Kies fluweel-specifieke verfstoffen voor optimale opname

2. Stof Voorbehandeling

- Weken in reinigingsoplossing om onreinigheden te verwijderen

- Grondig spoelen om klaar te maken voor kleurstofopname

3. Kledingproces

- Laad stof in de kleermachine

- Houd de precise temperatuur in stand

- Reguleer de vervenstijd

- Zorg ervoor dat de verf volledig doordringt

4. Nagaverfbehandeling

- Spoel af met schoon water om overbodige verf te verwijderen

- Behandeling toepassen voor kleurvastheid

5. De Kwaliteitscontrole

- Controle op kleurevenheid

- Vastheidstest (wassen/wrijven)

- Controle op textielintegriteit (samentrekking/pillen)

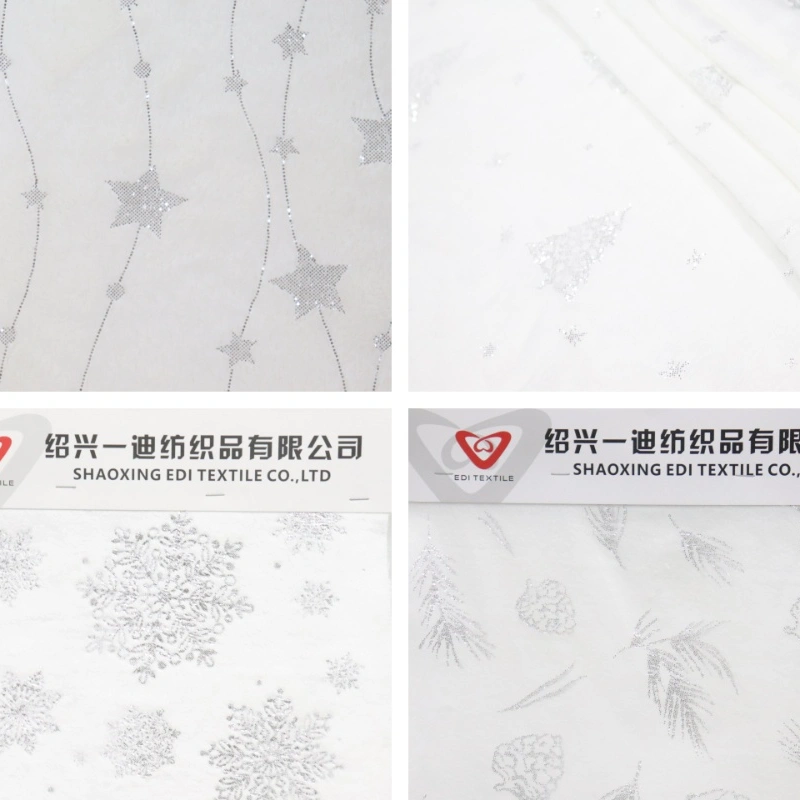

(3). Metaalfolie

Het thermisch stempelproces van flanel is een veelgebruikte decoratietechniek om het uiterlijk en de textuur te verbeteren. Thermisch stempelen kan tekst, patronen of decoratieve elementen zijn, meestal gemaakt via computerontwerpprogramma's of modellen. Kies het juiste thermische stempelfolie volgens de ontwerpeisen, wat goud, zilver of andere kleuren kan zijn. Pas de temperatuur en druk van de thermische stempelmachine aan naar de eigenschappen van flanel en de eisen voor thermische stempelfolie. Plaats de thermische stempelfolie in de ontworpen positie en gebruik een thermische stempelmachine voor het stempelen. Breng het patroon van de folie over op het oppervlak van de flanellen deken door middel van warmdrukken. Controleer het effect van het thermisch stempelen om ervoor te zorgen dat het patroon duidelijk, felgekleurd en vast is.

Hete stempeling van metaalfolie voor vilt

Procesoverzicht

1. Ontwerpvoorbereiding

- Maak patronen/tekst met CAD-software of gebruik aangepaste vormen

- Kies het folietype (goud/zilver/gekleurd) op basis van ontwerpeisen

2. Machinagebruik

- Pas de temperatuur aan (meestal 120-180°C)

- Druk optimaliseren (X-X psi) voor de vilt dichtheid

3. Hete Stansing

- Plaats folie precies op het vilt oppervlak

- Ontwerp overdragen via hittepers (X-X seconden bewaringstijd)

4. Kwaliteitscontrole

- Controleer helderheid, kleurintensiteit en haes

- Was- en wrijvtests uitvoeren voor duurzaamheid

Technische voordelen

C gebruikbaar – 50+ folie kleuropties

C gebruikbaar – 50+ folie kleuropties  Duurzaam – Kan 30+ industriële wasbeurten doorstaan

Duurzaam – Kan 30+ industriële wasbeurten doorstaan  Milieuvriendelijk – Low-VOC folies beschikbaar

Milieuvriendelijk – Low-VOC folies beschikbaar

Toepassingen:

- Luxe dekbedovertreks

- Merkenlogos

- Ontwerpen met een feestthema

MOQ: 500 eenheden | Levertijd: 25 dagen

Sleutelparameters

| Factor | Specificatie |

|---|---|

| Temperatuurbereik | 150°C ±5°C |

| Druk | 5-8 psi |

| Productiesnelheid | X eenheden/uur |

| Kleurvastheid | ≥4 (ISO 105-A02) |

Hebt u foliestalen of technische specificaties nodig? Neem contact op met ons team!

①. Goudfolie:

②. Zilverfolie:

③. Andere kleur:

(4). Jacquard

Flanel jacquard is een techniek die flanelstof en jacquard ambacht combineert, met unieke texturen en een mooie verschijning. Flanel jacquard stof staat bekend om zijn zachtheid, weelderige dekking, eenvoudige en elegante kleur, en goede warmte-isolatie. De weelderige structuur van flanel bedekt de stof zonder patronen zichtbaar te laten, en heeft een zacht en glad gevoel. Het heeft ook een hoge gewichtsgraad en een fijnzinnige, dichte weelderigheid, wat het uitstekend maakt in termen van warmte en uiterlijk. Jacquard-weven is een methode om patronen op stoffen te vormen, waarmee complexe en verfijnde patronen kunnen worden geweven, wat meer ontwerp en esthetiek toevoegt aan flanel.

Flanel Jakkaard: Luxueuze Textuur & Premium Warmte

Belangrijkste Kenmerken

Dubbel-Lagen Ambachtelijkheid: Combineert een zachte flanelbasis met ingewikkelde jakkaardweving

Handtekeningen Zachtigheid: Geborsteld oppervlak (170 - 350GSM) verbergt de weefstructuur volledig

Ontwerpverschilligheid : Produceert complexe patronen (bloemig/meetkundig/op maat) zonder comfort te compromitteren

Technische voordelen

Thermische prestaties – 30% warmer dan gewone flanellen

Thermische prestaties – 30% warmer dan gewone flanellen  Duurzaamheid – Houdt stand tegen 50+ industriële wasbeurten (ISO 6330)

Duurzaamheid – Houdt stand tegen 50+ industriële wasbeurten (ISO 6330)  Esthetische flexibiliteit – 200+ aanpasbare jacquardpatronen

Esthetische flexibiliteit – 200+ aanpasbare jacquardpatronen

Ideaal Voor:

- Hoogwaardige beddensets

- Luxe loungewear

-

Hotelkwaliteit dekens

Vergelijkingstabel

KENNISPAL Flanel jacquard Standaard flanel Patroon Ingeweven 3D ontwerpen Gedrukte/eenvormige kleuren Textuur Zijdeachtig glad met verborgen weefsel Gelijke oppervlakte structuur Warmte Uitmuntend (5-lagen luchtkussens) Goed MOQ 500m (op maat ontwerpen) 200m " Waar traditionele vakmanschap ontmoet moderne comfort - elk stuk vertelt een verhaal. "

(5). Drukstempeling

Reliëf aandrukken verwijst naar het proces van het samen aandrukken van een stof met een warme plaat, waardoor een oneffen effect zoals bloemen en patronen op het oppervlak van de stof wordt gecreëerd. De kenmerken van reliëf zijn dat het patroon diep is, het patroon duidelijk is, en de tactiele ervaringrijk is.

Geborsteld Flanel: Textuurrijke Elegantie

Proces & Kenmerken

Techniek: Warmtegedrukte patronen (120-180°C) met gegraveerde metalen platen

Kenmerkende Effecten:  3D Diepte: 0,5-2mm verhoogde patronen

3D Diepte: 0,5-2mm verhoogde patronen

Tactiele Definitie: Scherp geometrisch/floraal motifs

Tactiele Definitie: Scherp geometrisch/floraal motifs

Luxe Handgevoel: Contrasterende matte/glanz textures

Luxe Handgevoel: Contrasterende matte/glanz textures

T technische voordelen

Duurzaamheid: Houdt 85% van patroondiepte na 50 wasbeurten

Aanpasbaarheid: 100+ voorraadontwerpen of aangepaste vormen (MOQ: 200m)

Milieuvriendelijk: REACH-compatibel thermisch proces

Toepassingen:

Premiumprenten voor beddengoed

Boutiquejurk versieringen

Hoogwaardige binnenhuisdecoratie

Belangrijke specificaties

| Parameter | Detail |

|---|---|

| Drukdiepte | Aanpasbaar 0,3-3mm |

| Productiesnelheid | 15-20M/MIN |

| Kleurenopties | Alle vervenbare tinten |

| Voorbeeld levertijd | 5-7 Werkdagen |

"Verander eenvoudige flanel in tactiele kunst – waar elke aanraking een verhaal vertelt."

Vraag vandaag nog embossingmonsters aan met uw ontwerp!

(6). Knippen

De bloemsnijtechniek kan ondiepe groeven zoals omtreklijnen aan de randen van het patroon maken. Wanneer licht wordt geprojecteerd, ontstaat er een artistiek effect van "convexe reliëf", wat het patroon duidelijker, levendiger en perfect maakt. Daarnaast kan het snijproces ook tekortkomingen zoals onaantrekkelijke patronen en oneffen lijnen corrigeren, die worden veroorzaakt door bepaalde tapijtweefprocessen.

Nauwkeurig Flanel Knippen: Verbeterde Diepte & Heldere Afbeeldingen

Techniek Highlights

Laser-Guided Contouring: Creëert 0,2-0,5mm micro-groeven langs de randen van het patroon

Optische Verbetering: Lichtbreking produceert 3D "bas-reliëf" effecten

Kwaliteitscorrectie: Lost commun weaving fouten (oneffen lijnen/vervaagde motieven)

Belangrijkste voordelen

Patroondefinitie: 40% scherpere details t.o.v. standaard weefsel

Patroondefinitie: 40% scherpere details t.o.v. standaard weefsel  Tactiele-Visuele Synchronisatie: Groeven komen overeen met het ontwerp voor een coherente textuur

Tactiele-Visuele Synchronisatie: Groeven komen overeen met het ontwerp voor een coherente textuur  Defect Reductie: Verbetert:

Defect Reductie: Verbetert:

Onregelmatigheden in garenspanning

Patroonregistratiefouten

Variaties in vloerhoogte

Toepassingen:

Hoogoplosingslogobedekkingen

Architectuur-geïnspireerde huistextielen

Luxueuze automotiebinrichtingen

Technische Parameters

| Aspect | Specificatie |

|---|---|

| Groeven diepte | 0.2mm ±0.05 (aanpasbaar) |

| Tolerantie | ±0.1mm positionele nauwkeurigheid |

| Compatibele ontwerpen | Complexe geometrieën tot 1200dpi |

| Productiesnelheid | 8-12m²/uur |

" Waar precisie samenkomt met kunstenaarschap – elke snee verheft het ontwerpverhaal. "

Procesvergelijking

| Methode | Randdefinitie | Defectcorrectie | Bestemd Voor |

|---|---|---|---|

| Bloemsnee | ★★★★★ | ★★★★☆ | Premium merkartikelen |

| Standaardweefsel | ★★☆☆☆ | ★☆☆☆☆ | Basis textiel |

Beschikbaar met:

ECO Modus: Gereduceerd energieverbruik (-25%)

Hybride optie: Combineren met borduursel/digitale print

Vraag vandaag nog een defect-correctie casestudy aan!

(7). Borstelen

Flanelborstelen wordt bereikt door de vorm en grootte van flanel aan te passen, en verschillende vormen, maten en dichtheden aan het oppervlak toe te passen door mechanische op-en-neerbewegingen. Deze verwerkingsmethode kan interessante en driedimensionale patronen creëren, waardoor er een speciale visuele ervaring aan het product wordt toegevoegd.

Flanelen Techniek: Creëren van Tactiele Dimensie

Procesoverzicht

-

Aangepaste Texturering: Mechanisch borstelen met gevormde tools om te beelden:

Meetkundige patronen

Meetkundige patronen

Organische motieven

Organische motieven

Gemerkte logotipes

Gemerkte logotipes

-

Variabele effecten: Aanpasbaar door:

• Borstelvorm (rond/vlak/draad)

• Pile dichtheid (200-500 borstels/cm²)

• Stroke diepte (0,3-1,2mm)

Belangrijkste voordelen

3D-verlichting: Lichtspeelpatroon verhoogt de diepteperceptie met 60%

3D-verlichting: Lichtspeelpatroon verhoogt de diepteperceptie met 60%

Handtekening Touch: Meerlagig textuur verbetert greep en comfort

Handtekening Touch: Meerlagig textuur verbetert greep en comfort

Ontwerp flexibiliteit: 50+ voorraadpatronen of aangepaste vormgeving

Ontwerp flexibiliteit: 50+ voorraadpatronen of aangepaste vormgeving

Technische specificaties

| Parameter | Bereik |

|---|---|

| Diepgang van het patroon | 0,5-3 mm |

| Resolutie | Tot 20 lijnen/mm |

| Productiesnelheid | 10-15m/min |

"Verander plat fluweel in een interactieve doek – waar elke streep een verhaal vertelt."

Toepassingen

Luxueuze dekens: Richtingshalve borsteling creëert fluwelen lichteffecten

Ergonomische kleding: Geborstelde zones verbeteren thermoregulatie

Gelabelde artikelen: Aangepaste logo texturering

monsteropties:

① Standaard texturen bibliotheek

② Ontwikkeling van aangepaste tools (MOQ: 500m)

③ Hybride afwerkingen (gepoetst + gedrukt)

Vraag brushdemonstraties aan met je ontwerpbestand!

(8). Glow in the Dark / Luminous blanket

Het principe van lichtgevendheid berust op speciale milieuvriendelijke lichtgevende materialen, die overdag zonlicht of andere lichtbronnen absorberen en 's nachts in het donker natuurlijk licht uitstralen. Zacht en comfortabel, met een fijn gevoel, rijke elasticiteit en uitstekende isolatieprestaties. Na langdurig gebruik zal het niet vervormen of klossen, en het materiaal is zeer milieuvriendelijk, zonder irriterende geur, onschadelijk voor de huid, waardoor het thuis veiliger en gezonder wordt. Het vlakke en gladde oppervlak is gemakkelijk te reinigen, en de patroondruk valt niet snel af. Het kan in de wasmachine of handmatig gewassen worden, wat het erg gemakkelijk maakt om te gebruiken.

Glow-in-the-Dark Flannel Decken: Veiligheid ontmoet innovatie

Glow Technologie

P fosforescerende pigment: Opgeladen door zonlicht/kunstlicht (30 minuten = 8+ uur gloeien)

Eco-gecertificeerd: REACH & EN71-3 conform (niet-toxisch, kindveilig)

Premiumfuncties

Dubbele modus comfort:

Dubbele modus comfort:

Dag: Ultra-zacht 320GSM flanel

Nacht: Automatisch verlichte ontwerpen

Prestatie bevestigd:

Prestatie bevestigd:

50+ wascyclus (ISO 6330)

Geen pillen vorming (ASTM D3512)

Kleurvast printen (4-5 ISO 105)

Materiaalvoordelen

Huidvriendelijk: OEKO-TEX® Class I gecertificeerd

Lage Onderhoudskosten: Machinespoelbaar (30°C)

Duurzaam is: Anti-verstrikt weefstructuur

Technische specificaties

| Parameter | Specificatie |

|---|---|

| Luminantie | 150-200 mcd/m² (na 30 minuten opladen) |

| Opladecyclus | 10.000+ (70% helderheid behouden) |

| Stofgewicht | 320GSM ±5% |

| Gloeitijd | 8-10 uur (volledige duisternis) |

Toepassingen:

Veiligheiddekens voor de kinderkamer

Nood- en kampeeruitrusting

Thema-gebaseerde huiskamerdecoratie

" Lichtgevende comfort - waar veiligheid naadloos samenvalt met snijrandtextieltechnologie. "

Verpakkingsopties:

① Standaard: 3 gloeikleuren (blauw/groen/geel)

② Aangepast: Logo/patroon luminescentie (MOQ 500 stuks)

③ Pro: 30% gerecycled flanellenblends

Vraag glow prestatietestrapporten aan!

7.2.1 Wat is Glow in the Dark / Luminous Blanket ?

Flanel lichtgevende deken is een speciale deken die flanelstof en lichtgevende technologie combineert.

(1). Flanelstof

Kenmerken:

-Zacht en comfortabel: Flanel is een zeer zachte en compacte stof met een comfortabel gevoel.

-Sterke warmte: Deze stof heeft goede warmtewaardering en is geschikt voor gebruik in koude weersomstandigheden.

-Makkelijk te onderhouden: Flanel is doorgaans slijtagebestendig, rimpelvrij, gemakkelijk te reinigen en te onderhouden.

(2). Luminiscnte technologie

Kenmerken:

-Luminiscnte functie: Luminiscnte technologie maakt dat de deken gloeit in het donker. Meestal wordt het luminiscnt effect bereikt door speciale fluorescerende materialen toe te voegen aan de stof of door middel van oppervlaktecoating.

-Lichtopname en -emissie: Luminiscnte dekens nemen lichtenergie op in goed verlichte omgevingen en geven deze af wanneer er onvoldoende licht is (zoals 's nachts of in donkere omgevingen), waardoor licht wordt uitgestraald.

(3). Kenmerken van flanel luminiscnte deken

Combinatievoordeel:

-Comfort en warmte: Door de zachtheid en warmte van flanel te combineren, biedt het gebruikers een comfortabele gebruikerservaring.

-Nachtverlichtingseffect: Door nachtverlichtingstechnologie geeft de deken een zachte gloed in het donker af, wat de zichtbaarheid en plezier 's nachts verhoogt. Geschikt voor kinderen om te gebruiken, het kan helpen bij het verminderen van nachtelijke angsten.

-Versierend: Het lichtgevende effect kan de decoratieve waarde van de deken vergroten, waardoor het niet alleen praktisch is, maar ook een unieke binnenhuisdecoratie.

Toepassingsscenario's:

-Slaapkamer: Vooral geschikt voor kinderkamers, het biedt zowel comfort als nachtverlichting, wat kan helpen bij het inslapen van kinderen.

-Woonkamer: Als thuisdecoratie kan het warme verlichting bieden 's nachts.

-Reizen: Geschikt voor nachtelijk reizen, het biedt extra comfort en veiligheid.

(4). Gebruik en onderhoud

-Verlichtingsbronvereisten: Om een goed nachtverlichtingseffect te behouden, moet de deken overdag of in een goed verlichte omgeving worden blootgesteld aan lichtenergie.

-Reinigingsmethode: Meestal kan het schoongemaakt worden volgens de verzorgingsvereisten van flanelstof. Het wordt aanbevolen om een zacht wasmiddel en koud water te gebruiken, en hoge temperaturen en krachtige wasbehandelingen te vermijden om het lichteffect te beschermen.

- samenvatting -

De flanelverlichte deken is een uniek product dat de comfort van flanel combineert met verlichtingstechnologie, waardoor uitstekende warmte en nachtvisibiliteit wordt geboden. Het is geschikt voor kinderkamers, interieurdecoratie en nachtelijk reizen, en biedt gebruikers comfort en gemak.

Glow-in-the-Dark Flannel Dekens: De Slimmere Comfortoplossing

Innovatief Dual-Function Ontwerp

Combinatie van premium flanellen comfort met zelfverlichtende veiligheidsfuncties

1. Premium Flanel Basis

-

Uiterst Zachte Structuur: 320GSM geborsteld polyester (OEKO-TEX® gecertificeerd)

-

Thermische prestaties: Houdt 30% meer warmte vast dan standaard fleece

-

Makkelijke verzorging: Machinespoelbaar op 30°C, anti-knobbeltbehandeling

2. Geavanceerde Luminous-technologie

-

Zelf opladen: 30 minuten lichtexpositie = 8-10 uur nawerking

-

Eco-Safe: Niet-toxische strontiumaluminaat pigmenten

-

Duurzaamheid: Houdt 80% luminositeit na 50 wasbeurten aan

Belangrijkste voordelen

Kindveilig comfort: Softer dan katoen, gloed vervangt nachtlampjes

Kindveilig comfort: Softer dan katoen, gloed vervangt nachtlampjes  Meerdaadse gebruik:

Meerdaadse gebruik:

- Kinderkamernoodzakelijk (vermindert nachtangst)

- Noodverlichting (kamperen/stroomuitval)

-

Sfeervolle thuisdecor

Commercieel klaar: Aangepaste logos/patronen (MOQ 200 stuks)

Commercieel klaar: Aangepaste logos/patronen (MOQ 200 stuks)

Technische specificaties

| Kenmerk | Prestatiegegevens |

|---|---|

| Lichtheid Intensiteit | 180-220 mcd/m² |

| Opladecyclus | 10.000+ (5-jarige levensduur) |

| Warmtebehoud | 0,8-1,2 CLO-waarde |

"Veiligheid en comfort dat dag en nacht werkt – geen elektriciteit nodig."

Zorginstructie s

1. Opladen: 30 minuten zonlicht/ruimtelicht per dag

2. Wassen: Koude zachte wascyclus, mild wasmiddel

3. Drogen: Lucht drogen of laag toerental (≤40°C)

Bestelopties:

-

Standaard (90×120cm, 3 gloedkleuren)

-

Aangepast (grootte/patroon/luminantie aanpasbaar)

Vraag vandaag gratis gloeiprestatie monsters aan!

Waarom professionals ons kiezen:

-

FDA-goedgekeurde lichtgevende materialen

-

72-uurs prototype service

-

OEM/ODM beschikbaar

Verlichtingshelderheid vergelijkingsgrafiek beschikbaar op verzoek

7.2.2 Hoe wordt een Flanel Glowing in the Dark / Verlichte Deken Gemaakt?

Het productieproces van de verlichte flaneldeken omvat de volgende belangrijke stappen:

(1). Materialen kiezen

-Flanelstof: Kies zachte en comfortabele flanelstof als basis voor de deken. Flanel bestaat meestal uit polyestervezels, die goede warmte en zachtheid bieden.

-Luminescerende materialen: Selecteer speciale luminescerende poeders of coatingmaterialen die lichtenergie kunnen opnemen wanneer er voldoende licht is en in het donker licht uitstralen.

(2). Stofvoorbereiding

-Schoonmaken en oplossen: Voer een voorbehandeling uit op de flanelstof, inclusief schoonmaken en oplossen, om de reinheid en stabiele kwaliteit van de stof te waarborgen. Deze stap helpt om onreinigheden en overbodige vezels uit de stof te verwijderen.

-Snijden: Snijd de stof naar de gewenste grootte en vorm volgens de ontwerpeisen.

(3). Voeg luminescerende materialen toe

-Coating: Breng luminescerend materiaal aan op de flanelstof. Meestal worden luminescerende materialen in een speciale coatingvorm aangebracht, door spuiten, schilderen of doven met luminescerend poeder gelijkmatig op het oppervlak van de stof.

-Mengen: In sommige gevallen kan luminescerend poeder worden gemengd met lijm of andere lijmstoffen en worden aangebracht om te waarborgen dat het luminescerende materiaal stevig aan de stof vastzit.

(4). Drogen en harden

-Droogtijd: Droog het met luminescent materiaal beklede weefsel. Deze stap moet meestal bij een specifieke temperatuur en luchtvochtigheid worden uitgevoerd om ervoor te zorgen dat het luminescent materiaal volledig droogt en vastzit.

-Verharden: Soms zijn extra verhardingsstappen nodig om de hechting en duurzaamheid van luminescent materialen te verbeteren. Dit kan inclusief hitteverharding of chemische verharding behandelingen zijn.

(5). Naaien en montage

-Naaien: Naai het verwerkte viltweefsel tot de eindvorm van de deken. Dit omvat samenvoegen, randen naaien en toevoegen van eventuele decoraties.

-Kwaliteitscontrole: Nadat het naaien is voltooid, wordt er een kwaliteitscontrole uitgevoerd op de deken om een uniforme lichteffect te waarborgen, stevig genaaide stof en geen tekortkomingen.

(6). Verpakking en distributie

-Verpakken: De voltooide viltluminescente deken wordt verpakt met beschermende verpakkingmateriaalen om te zorgen dat deze tijdens het transport niet beschadigd raakt.

-Distributie: Distribueer verpakte dekens naar verkoopkanalen of rechtstreeks naar klanten.

(7). Gebruik en onderhoud

-Lichtbron blootstelling: Tijdens het gebruik moet de lichtgevende deken regelmatig blootgesteld worden aan een lichtbron om te waarborgen dat hij voldoende lichtenergie kan opnemen en in het donker licht geeft.

-Schoonmaken en onderhoud: Schoon volgens de reinigingsvereisten voor fluweel, meestal met koud water en een zacht wasmiddel, en vermijd hoge temperaturen en krachtige wasbehandelingen om het lichtgevende effect te beschermen.

- samenvatting -

Het proces om fluweel lichtgevende dekens te maken omvat materiaalselectie, stofverwerking, toevoeging van lichtgevende materialen, drogen en verharden, naaien en montage, en uiteindelijk verpakken en distribueren. Door deze reeks gedetailleerde productiestappen biedt de fluweel lichtgevende deken een comfortabele aanraking en een uniek lichtgevend effect.

Productieproces van nachtverlichtende flanel dekens

1. materiaalkeuze

- Basisstof : 320GSM polyesters flanel (OEKO-TEX® gecertificeerd)

- Luminescerend component : Strontiumalumina pigmenten (150-220 mcd/m² helderheid)

2. Stofvoorbereiding

Voorbehandeling:

Ultrasone reiniging om onreinigheden te verwijderen

Ultrasone reiniging om onreinigheden te verwijderen  Nauwkeurig knippen (±2mm tolerantie)

Nauwkeurig knippen (±2mm tolerantie) - Kwaliteitscontrole: Controleer GSM-gewicht en vilt dichtheid

3. Luminiscente Toepassing

- Methode: Schermprinten met fosforescerende inkt (60-80g/m² coating)

- Alternatieve Techniek: Garen-integratie voor geweven ontwerpen

-

Verkopen:

behandeling bij 120°C (3-5 minuten)

behandeling bij 120°C (3-5 minuten)  Test op UV-weerstand

Test op UV-weerstand

-

4. Productiemontage

-

Naaien:

3-draad overlock naad (12 steken/inch)

3-draad overlock naad (12 steken/inch)  Controle van gloeipatroonuitlijning

Controle van gloeipatroonuitlijning

-

Kwaliteitscontrole tests:

Luminantiecontrole (test in donkere kamer)

Luminantiecontrole (test in donkere kamer)  Wasduurzaamheid (certificering van 50+ cycli)

Wasduurzaamheid (certificering van 50+ cycli)

-

5. Verpakking & Logistiek

- Beschermend verpakking: Vakuumverpakt met antistatische laag

- MOQ: 200 eenheden (op maat ontwerpen)

- Levertijd: 15-20 dagen na goedkeuring

Belangrijke technische parameters

| Procesfase | Specificatie |

|---|---|

| Luminantie | ≥150 mcd/m² (na 30 minuten opladen) |

| Wasweerstand | ≤15% helderheidverlies na 50 wasbeurten |

| Lijmkachtheid | 4/5 (ASTM D3359) |

| Productiecapaciteit | 1.000 eenheden/dag |

Kwaliteitscertificaten:

-

EN71-3 (Speelgoedveiligheid)

-

REACH SVHC-conform

-

ISO 6330 Wasstandaard

Zorgvoorzieningen

-

Opladen: 30 minuten onder 500+ lux licht

-

Afspoelen: Koude delicate wascyclus (<30°C)

-

Droogenen: Alleen lucht drogen

"Ontworpen voor een nachtelang vonken – waar veiligheid samenkomt met innovatie in elke draad."

Aanpasbare Opties Beschikbaar:

① Vonk kleur (blauw/groen/geel)

② Patrooncomplexiteit (tot 8 kleuren)

③ Maatbereik (50x60cm tot 200x220cm)

Vraag onze productiewitboek aan voor volledige technische details.

8. Hoe verschilt het van normale fluweeldekens van merken?

EDITEX, met meer dan 20 jaar ervaring in de productie van flaneldekenen.

EDITEX, een merk dat synoniem staat met uitstekende vakmanschap en ongeëvenaarde zachtheid.

Ons fluweel is zorgvuldig vervaardigd uit de beste materialen, wat een luxueuze ervaring garandeert die verder gaat dan slechts warmte.

(1). De essentie van luxe

We geloven dat comfort niet het antwoord op alles hoeft te zijn. Onze flanel is ontworpen om zowel gezellig als sofistiek te zijn. We gebruiken alleen de beste, duurzaam geëxploiteerde materialen, zodat onze producten zowel luxueus als milieuvriendelijk zijn.

(2). Onnavolgbaar Kwaliteit

Onze flanellen deken wordt zorgvuldig vervaardigd om uitzonderlijke kwaliteit en duurzaamheid te waarborgen. Vanuit het gedetailleerde weefproces zijn we trots op elk detail. Onze flanel is ongelooflijk zacht, warm en ademend, wat uiteindelijke comfort biedt aan iedereen van jullie.

(3). Een Verscheidenheid aan Keuzes

We bieden een breed scala aan stijlen en kleuren om ieders voorkeur te voldoen. Of je nu naar een klassiek ruitpatroon, een modern geometrisch ontwerp of een gloei-in-het-duister print zoekt, we hebben de perfecte flanel om jouw ruimte te verbeteren.

(4). Ervaar het verschil

Het moment dat je onze flanellen deken aanraakt, begrijp je dat onze flanel niet gewoon een stof is; het is een verklaring van luxe en comfort. Embrace de gezelligheid en elegantie die alleen EDITEX kan bieden.

Wat maakt EDITEX Flanellen Dekens uniek?

Sinds meer dan 20 jaar , heeft EDITEX de luxe van flanel herschreven door nauwkeurige vakmanschap en onverzettelijke kwaliteit .

Waarom EDITEX boven gewone flanel uitsteekt

Luxe opnieuw gedefinieerd

Luxe opnieuw gedefinieerd

-

Meer dan alleen warmte – Een sensorische ervaring met fluweelzachte zachtheid (170 - 350 GSM)

-

Eco-Premium Materialen: GRS-gecertificeerde gerecyclede polyester & OEKO-TEX® verf

Gecreëerde Excellentie

Gecreëerde Excellentie

- Dubbel geborsteld finish voor een wolkachtige textuur

- 3x houdbaarheid t.o.v. standaard flanel (50+ industriële wasbeurten)

- Temperatuurregulerend weven voor comfort in alle seizoenen

Ontwerp Zonder Grenzen

Ontwerp Zonder Grenzen

-

200+ patronen (van klassieke tartans tot lucht-in-het-duister prints )

-

Aangepaste OEM/ODM diensten (MOQ 500 eenheden)

De EDITEX Touch

De EDITEX Touch

-

Direct herkennen: Onze flanellen gordijnen 30% gladser

-

Luxueuze verpakking: Direct geschikt als cadeau met antistatische opslag

"Gewone flanellen houden je warm. EDITEX flanellen verandert hoe je comfort ervaart."

Ontdek het EDITEX verschil:

① Aanvraag gratis monsterkaartjes (Vergelijk naast elkaar met concurrenten)

② Vraag naar onze VIP grootschalige bestelprogramma

③ Download onze flanel Zorggids voor premium onderhoud

9. Veel Gestelde Vragen (FAQ)

(1). Wat is de Minimale Bestelhoeveelheid (MOQ) van flanel?

EDITEX accepteert een minimum hoeveelheid van 350kg voor verven en 1000kg voor printing. Volgens de verschillende behoeften van klanten geven we verschillende MOQ.

(2). Zijn er beschikbare hoeveelheden van flanel?

EDITEX heeft veel flanelstof op voorraad. En we hebben stock flanel dekens tegen lage prijzen, die aan iedere klantvraag voldoen.

(3). Welke certificaten heeft EDITEX?

EDITEX heeft GRS en OEKO-TEX certificaten. Hecht grote waarde aan duurzame ontwikkeling.

(4). Toepassingen van flanel:

Deeltjes rechthoekige en ronde dekens met afdrukken van elk patroon kunnen aangepast worden.

Badjas : Flanel fleece heeft een goede handgevoel. Super zacht en duurzaam, zeer geschikt voor gevoelige huid. Bovendien heeft het een goede wateropname.

Pyjama : Deze fleece is anti-pilling en zal niet vervaagen. Maak je geen zorgen over allergische symptomen. De stof die we gebruiken is hypoallergenisch.

HOODIE DEKEN : Om de leefstandaard thuis te verhogen, hebben we deze hoodie deken met grote zakken gelanceerd. Draag hem tijdens het kijken van televisie of lezen, wat je kan ontspannen.

2 in 1 deken : Je moet moe zijn na een zakenreis of een lange reis, dan is deze 2 in 1 deken geschikt voor jou. Het kan worden opgevouwen in een kussenhoes en veilig vastgemaakt aan de romp. Elke keer als je een dutje wilt doen, open je het ritsje en krijg je een deken.

(5). Kenmerken van flanel:

- Vers

- DUURZAAM

- Gezellig

- Milieuvriendelijk

- Geschikt voor vier seizoenen

- Anti-pilling

- Hypoallergisch

- Goede wateropname

(6). Hoe verzorg je flanel of hoe was je een flanellen vloerkleed?

Om flanel zacht en knus te houden, was het in de wasmachine met koud water op een zachte cyclus met mild wasmiddel. Vermijd het gebruik van bleekmiddelen of stofzachters. Droog op lage warmte in de droger of laat drogen aan de lucht. Voor koppige vlekken reinig je puntsgewijs met een oplossing van mild zeep en water. Bewaar je flanel in een koel, droog plaats om vervaarding en verkleuring te voorkomen.

Dit zal helpen om je flanel artikelen in goede staat te houden voor een lange tijd.

EDITEX Flanel: FAQ (Veel Gestelde Vragen)

1. Minimale Bestelhoeveelheid (MOQ)

-

Verfservice : 350 kg

-

Drukdiens : 1000kg

Flexibele MOQ voor aangepaste projecten – Neem contact op om uw behoeften te bespreken.

2. Voorraadbeschikbaarheid

Paraat voor verzending:

Paraat voor verzending:

- 50+ flanellen stoffen op voorraad

- Korting op voorraadbladen (levering binnen 3-5 dagen)

3. Certificaten

- GRS (Global Recycled Standard)

-

OEKO-TEX® Standard 100 (Classe I voor babyveiligheid)

Duurzame productie met ≤0.1% chemisch afval

4. Premium toepassingen

| Product | Belangrijkste voordelen | Bestemd Voor |

|---|---|---|

| Deeltjes | 200+ aangepaste prints, anti-pilling | Thuis/Hotel gebruik |

| Badjassen | 420GSM plush, 5s wateropname | Spas/Luxueuze resorts |

| Pyjama's | Hypoallergenisch, vervaagbestendig | Gevoelige huid |

| Hoody dekens | Aantrekbaar met XL zakken | Thuiswerken comfort |

| 2-in-1 Reisdekens | Kan omgevormd worden tot kussen (opstelbaar in 30 seconden) | Zakenreizen/kamperen |

5. Waarom Kiezen Voor Flanel?

Comfort Voor Alle Seizoenen (GSM opties: 180-350)

Comfort Voor Alle Seizoenen (GSM opties: 180-350)  Milieubewust – 30% gerecycled materiaalopties

Milieubewust – 30% gerecycled materiaalopties  Duurzaamheid – Houdt stand tegen 50+ industriële wasbeurten

Duurzaamheid – Houdt stand tegen 50+ industriële wasbeurten  Hypoallergen – OEKO-TEX® gecertificeerde veiligheid

Hypoallergen – OEKO-TEX® gecertificeerde veiligheid

6. Wasinstructies

-

Wassen: Koud water (≤30°C), zachte wasmiddelen

-

Drogen: Laag warmte of lucht drogen

-

Mijden: Chloor/stofverzachters

-

Opslag : Opbergen in een koel, droog plaats

Pro-Tip: Was binnenstebuiten om prints te behouden

EN

EN